BLOOB COFFEE TABLE

Mahogany rubber ply, Baltic birch ply, glass, fiberglass

The BLOOB Coffee table sat spinning in computer space for three years before I figured out how to make it.

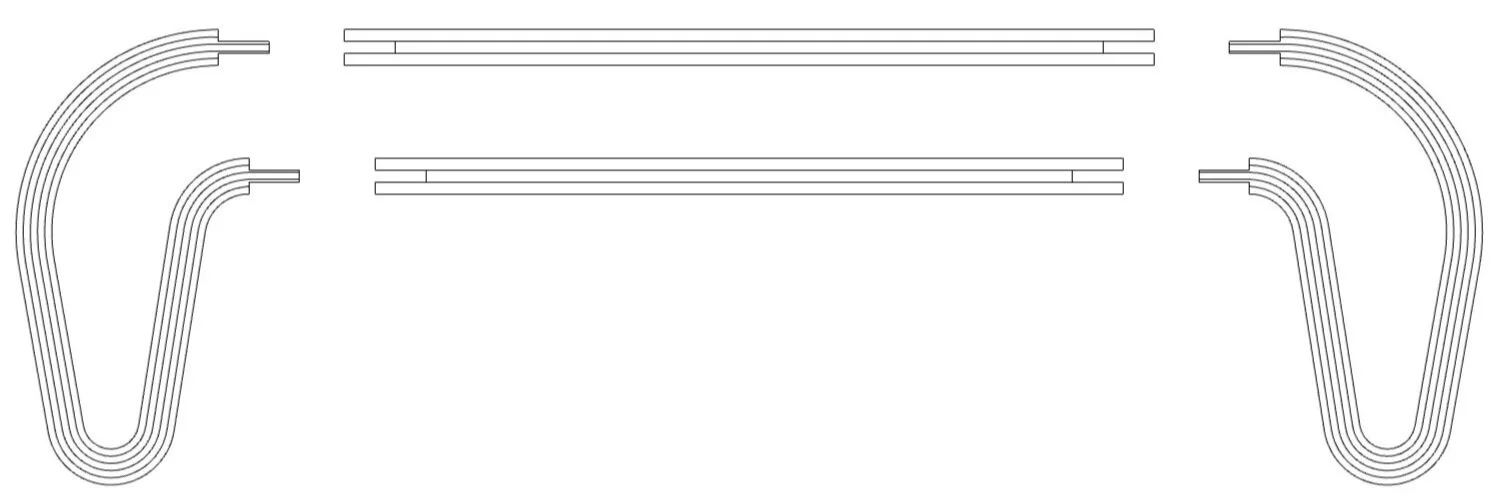

The solution involved securing two straight sections each composed of 3 layers of 12mm Baltic birch ply between two bent wood sections each composed of 5 layers of 7mm mahogany rubber ply.

The bent wood sections were created using a two-piece form in a vacuum bag press.

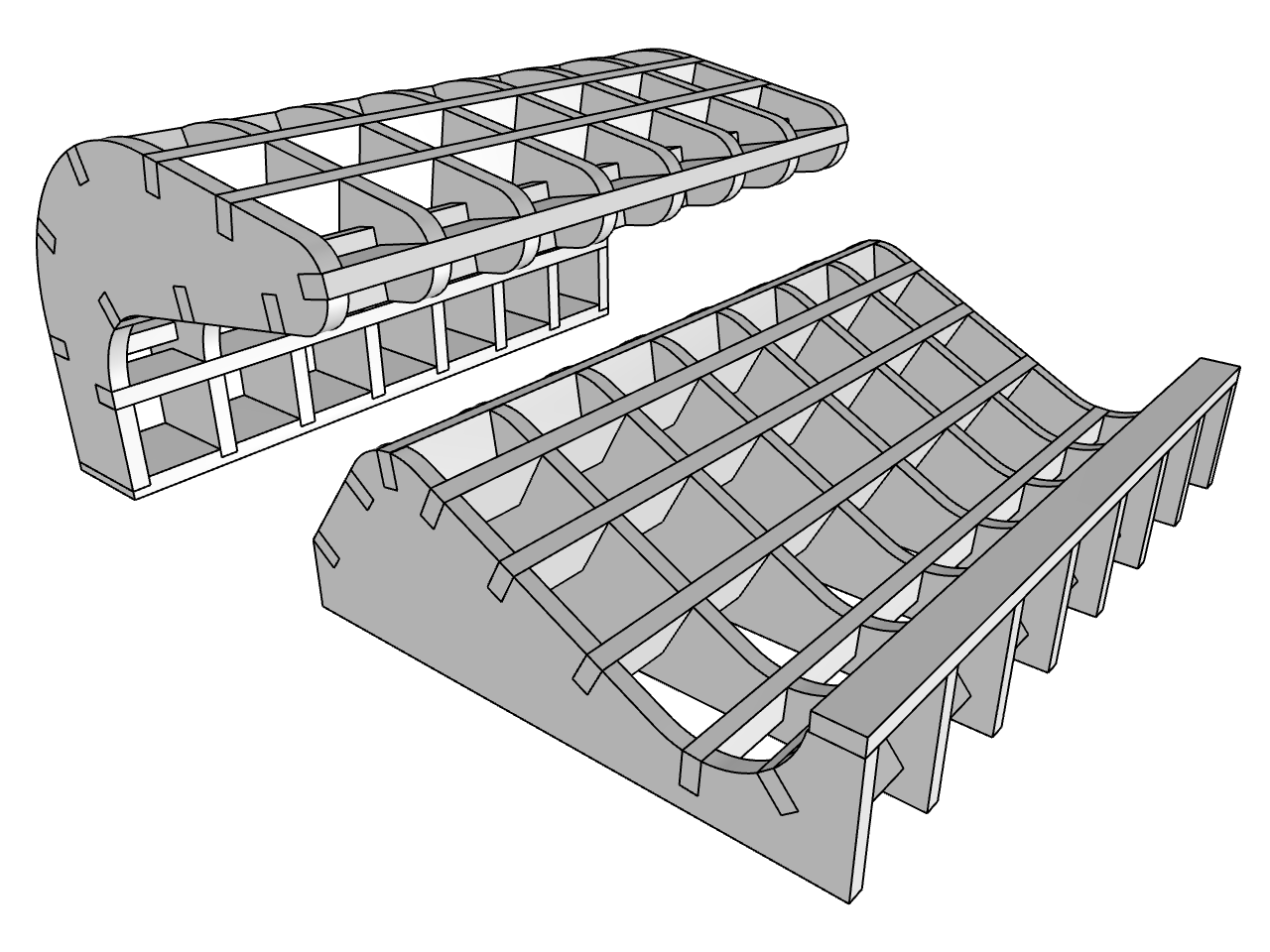

Extremely strong bag press forms can be created very quickly and efficiently by cutting slotted components into flat stock such as MDF using a CNC router.

Under the intense pressure of a vacuum bag, the two-part form creates an exceptionally sturdy bent wood component.

Once assembled, the entire table was wrapped in fiberglass and polyester resin to add further durability and stiffness, before having the sides cut into their distinctive form.

Primer was then applied.

The metallic finish was achieved by mixing powdered pewter with a urethane semi-gloss clear coat.

6 - 8 applications give the finish a true depth.